Fully Automatic Strawberry Juice Processing Machines CIP Cleaning

Available

Description

Shanghai Gofun machinery company, a professional berry processing

line manufacturer and exporter in China. Which can provide turnkey

solution and technical support for berry processing line with all

kinds of package.

The juice processing line is to produce original berry juice after

the fresh berry has been floated, crushed, juiced, hydrolyzed,

ultra-filtered, concentrated, sterilized, and filled. The entire

line is designed for berry juice according to international quality

standards.

1. Washing and sorting: Sort out the berry that does not meet the requirements and convey

them to the designated location, reducing labor cost.

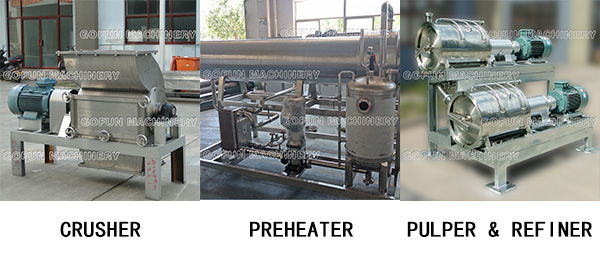

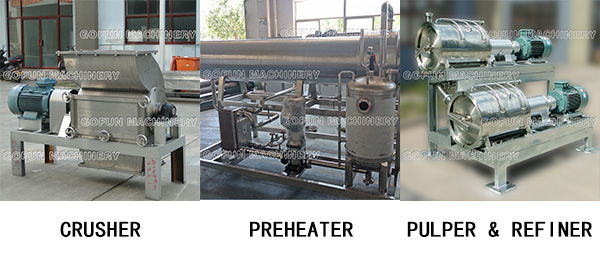

2. Crush: The berry granules are refined by hammer breaking, and the

crushing process is protected by nitrogen gas.

3. Juice extraction: Juice is extracted by a special process, which adjusted juice to

increase the juice productivity.

4. Sterilization: Retaining the color and taste of juice through UHT instant

sterilization technology.

5. Aseptic filling: storage in sterile large bags to improve the shelf life of the

juice.

| Raw material | Raspberry, strawberry, blueberry, wolfberry, mulberry etc. |

| End product | Juice, beverage, paste, jam, dried berry |

| Processing capacity | From 20 T/day to 1500 T/day |

| Juice yield | 85% raw fruit (15% as waste, peels and seeds) |

| End package | Aseptic bag, metal can, glass bottle, PET bottle, etc. |

Advantages

1. All equipment in the system is made of stainless steel (directly

in contact with the raw material part), based on the most advanced

processing technology.

2. The whole process design and pipe connection arrangement is

conducive to the preservation, cooling, heat treatment and

short-term transmission of natural aroma components of fruits and

vegetables, effectively preventing the loss of flavor and substance

in the heat reaction; it can also reduce the quality loss caused by

oxidation reflection under high temperature conditions.

3. The entire production line is fully enclosed, surrounded by

crushing, water-cooled separation, concentration, sterilization,

filling and aseptic environment to maximize the original flavor and

nutrients.

4. The operation of the control part adopts automatic control

system, automatic fault alarm system, all-round safety mechanism,

safety equipment and personnel safety; All electronic control

system components are from international famous brands such as

Siemens, Omron and so on.

5. The type of steam control in the production line (very

important, related to product quality) comes from the world-famous

steam control system brand Spirax Sarco, with convenient control

and high reliability, which effectively guarantees the balance of

quality and purity of different batches of products.

6. The main equipment is from our long-term cooperation suppliers

to ensure reliable and controllable equipment; accuracy of

parameters; stability and safety.

Flowchart

Berry Juice Processing Line

FRESH BERRY ⇒ CONVEYOR ⇒ WASHING ⇒ SORTING ⇒ CRUSHING ⇒ PREHEATING ⇒ PULPER &

REFINER ⇒ ENZYMATIC HYDROLYSIS & FILTRATION SYSTEM ⇒ STERILIZING ⇒

ASEPTIC FILLING ⇒ STORAGE OR BLENDING

Related Machine

Company Information

Shanghai Gofun machinery company, a professional fruit and

vegetable processing line manufacturer and exporter in China. Which

can offer the turn-key solution for different fruits juice, pulp &

paste processing complete line with high quality and competitive

production lines with daily capacity from 60 tons to 1500 tons and

customizations including plant construction, equipment

manufacturing, installation, commissioning and production; provide

the most optimized implementation plan.Gofun Company provides the

turn-key solution for not only the tomato paste production line but

also the processing lines for many kinds of fruits & vegetables,

like apples, pears, plums, coconuts, mulberries, ect., and has

received widespread praises from customers from both the domestic

and overseas. Our machines have already been exported to all over

the world including the Asian countries, African countries, South

American countries and even European countries.

| Business Type | Manufacturer | Country | China |

| Main Products | Turn Key Solution for Fruit & Vegetable Processing and Packaging

Complete Line | Capacity | 30 sets per year (whole line) |

| Established Year | 2009 | Main Market | Africa, South Ameria, Asia, Europe |

Our Services

Pre-Sales Service

1. Technical support

2. Marketing suggestion

3. Final packing suggestion and design

4. Factory building and design

After-Sales Service

1. Comprehensive engineering services

2. Installation supervision

3. Operator training

4. Oversea technical support

5. Oversea equipment maintenance

6. English speaking engineers available to provide technique

support