Description

Gofun Machinery stands out for its complete pineapple processing

line, facilitating the creation of a wide array of final products

sourced from fresh pineapples. This line encompasses pineapple

juice, concentrated juice, beverages, jams, dried pineapple, and an

assortment of other goods. Packaging choices for these products are

diverse, ranging from aseptic bags, sachets, stand-up pouches,

metal cans, PP containers, PET bottles, glass bottles, capped

bottles, and beyond.

Some of the most popular industrial pineapple processing production

lines are:

1. Pineapple Juice Concentration Processing Line

2. Pineapple Juice Processing Line

3. Pineapple Beverage Processing Line

4. Dried Pineapple Processing Line

| Raw material | Fresh pineapple |

| End product | Concentrated juice or clear juice, beverage, jam, dried fruit, etc |

| Capacity | 3 tons / day -1500 tons / day, according to customer |

| Juice yield | 40~50% |

| Initial sugar content | About 14% Brix |

| Terminal sugar content | 58-60 Brix |

| Product packaging | Aseptic bag, glass bottle, PET bottle, Metal can and etc |

A pineapple juice production line typically includes multiple steps

and equipment to produce and package fresh pineapple juice. Here

are the steps and equipment a typical pineapple juice production

line might include:

- Washing and Peeling: The initial step involves washing and peeling

the pineapples before they are introduced into the production line.

- Cutting and Coring: Following washing, the pineapples are sliced

into appropriately sized chunks with the removal of the tough core.

- Juicing: The prepared pineapple pieces are fed into a juicer to

extract fresh pineapple juice.

- Filtration: The extracted pineapple juice undergoes filtration to

eliminate solid particles and fibers, ensuring a smooth and refined

taste.

- Pasteurization (if required): In certain cases, the pineapple juice

is pasteurized at this stage to prolong its shelf life.

- Filling and Packaging: The processed pineapple juice is dispensed

into bottles, bags, or alternative containers, which are then

sealed and prepared for distribution.

- Labeling and Final Product Inspection: Packaged pineapple juice

containers are labeled and meticulously inspected to verify

adherence to quality standards before they are made available for

sale.

The size and equipment of a pineapple juice production line will

vary depending on production needs and scale, but will typically

include the above steps to ensure a high-quality pineapple juice

product.

Features

- The processing line is adaptable to a broad spectrum of production

capacities, spanning from 20 tons per day to 1500 tons per day,

effectively catering to diverse production demands.

- Tailored to process fruits with akin characteristics, the line

offers versatility in handling a variety of fruit types.

- An automated disinfection control system guarantees precise

management of disinfection liquid concentration, heightening

sterilization efficacy, and regulating disinfection residue levels.

- Integration of a tubular-type pasteurizer enhances pineapple output

rates, leading to improved production efficiency.

- Employing a high-efficiency belt juice extractor elevates juice

extraction efficiency and yield, optimizing overall production

output.

- An automatic PLC-controlled production process diminishes labor

intensity, boosts production efficiency, and fosters energy

conservation.

- Utilization of low-temperature vacuum evaporation minimizes flavor

substance and nutrient losses during processing, safeguarding the

quality of the final product.

- Diverse energy recovery techniques are implemented to enhance

energy utilization efficiency, markedly reducing production costs.

- Safety precautions, such as a UHT sterilizer and aseptic filling

machine, safeguard food products from bacterial contamination,

ensuring product safety and prolonging shelf life.

- Incorporation of a self-sufficient CIP (clean-in-place) system

throughout the production line lessens labor intensity, upholds

elevated hygiene standards, and conserves resources and time.

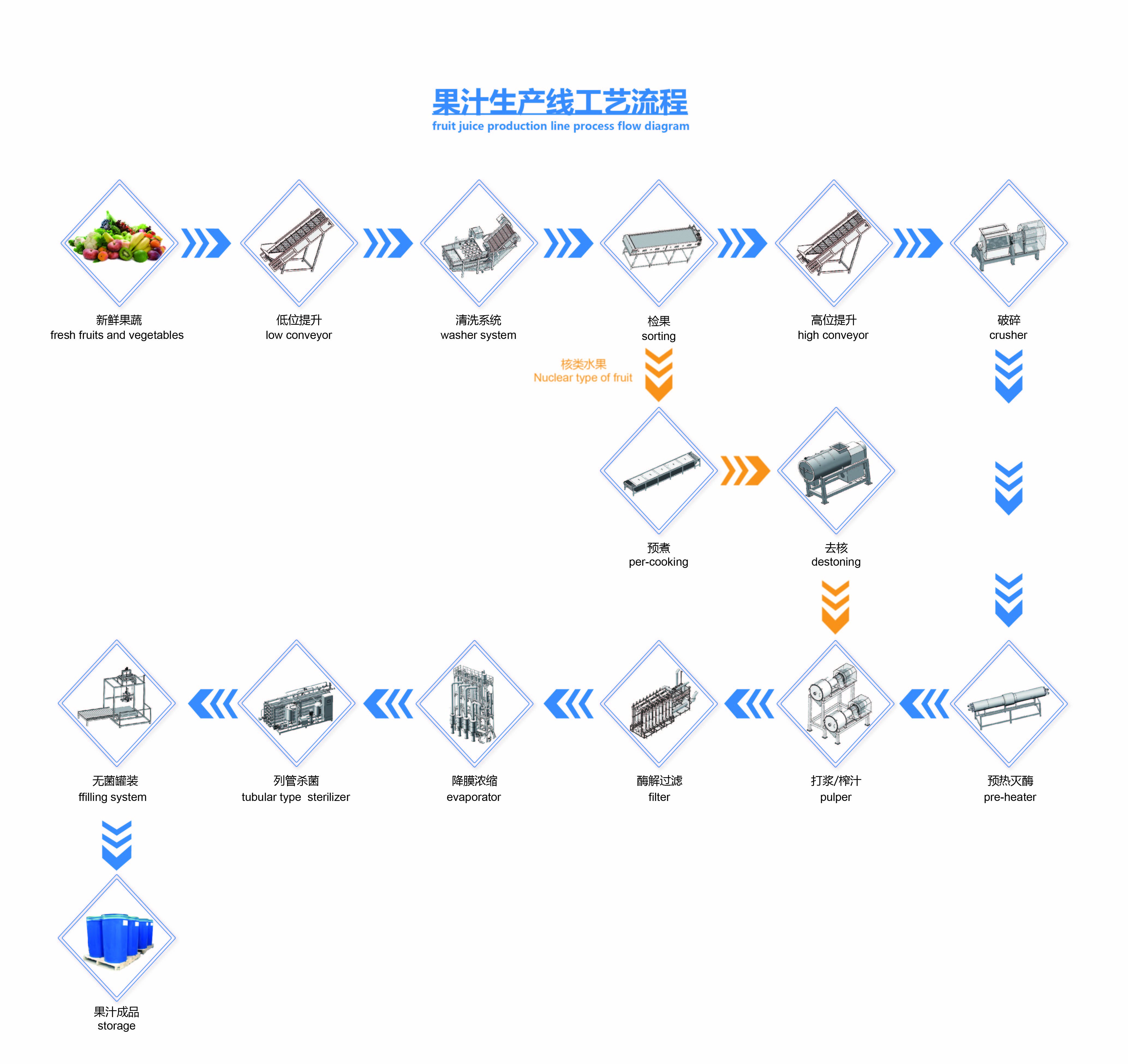

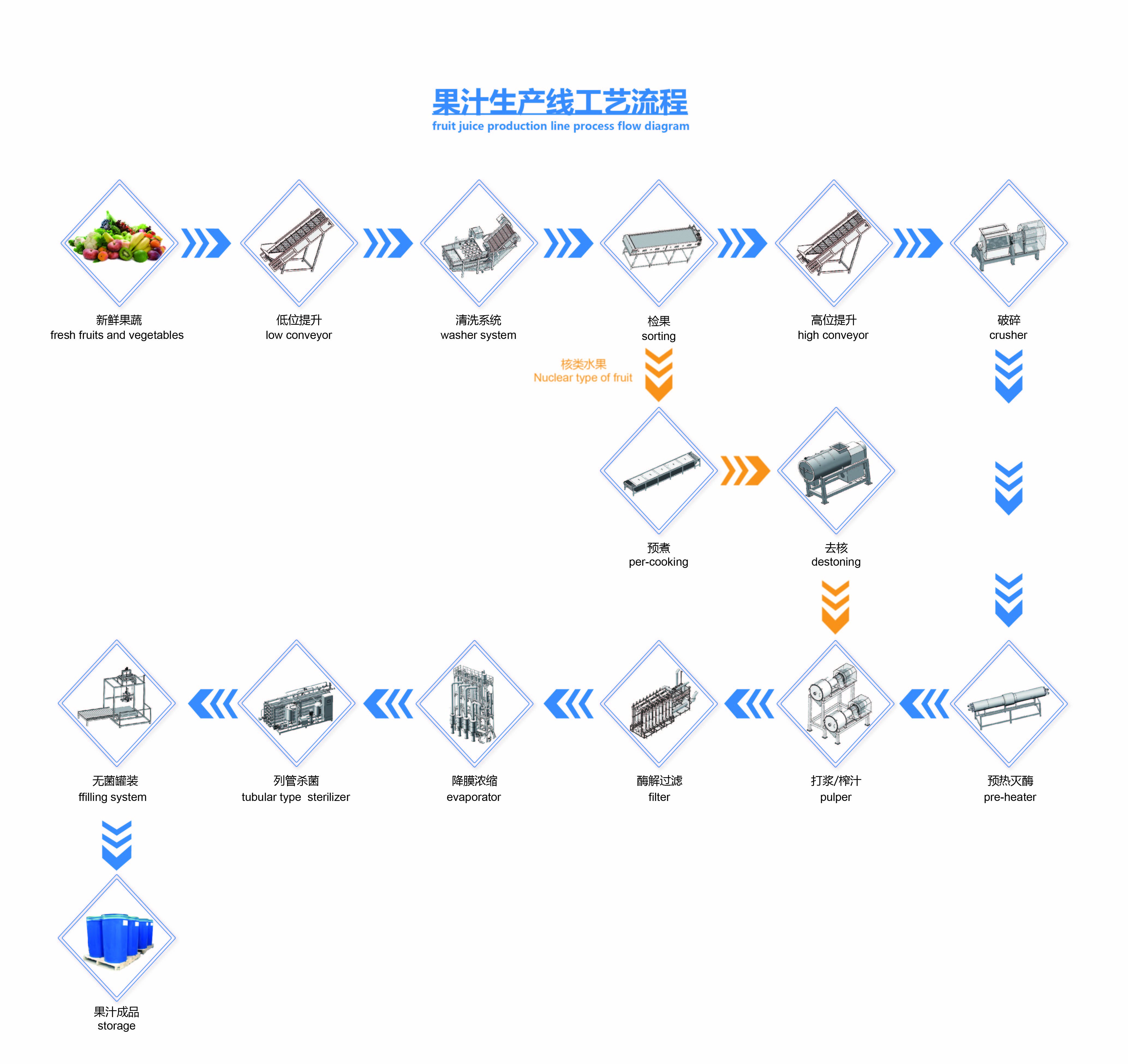

Flowchart

Pineapple Juice Concentration Processing Line

FRESH PINEAPPLE ⇒ CONVEYOR ⇒ WASHING ⇒ SORTING ⇒ CRUSHING ⇒ BELT TYPE JUICE EXTRACTING ⇒ ENZYMATIC HYDROLYSIS & FILTRATION SYSTEM ⇒ EVAPORATING ⇒

STERILIZING ⇒ ASEPTIC FILLING ⇒ STORAGE OR BLENDING

Pineapple Juice Processing Line

FRESH PINEAPPLE ⇒ CONVEYOR ⇒ WASHING ⇒ SORTING ⇒ CRUSHING ⇒ BELT TYPE JUICE EXTRACTING ⇒ ENZYMATIC HYDROLYSIS & FILTRATION SYSTEM ⇒ STERILIZING ⇒ ASEPTIC

FILLING ⇒ STORAGE OR BLENDING

Pineapple Beverage Line

PINEAPPLE CONCENTRATION⇒ BLENDING SYSTEM ⇒ STERILIZING ⇒ FILLING ⇒

PASTEURIZING TUNNEL ⇒ PACKAGING

Dried Pineapple Processing Line

FRESH PINEAPPLE ⇒ CONVEYOR ⇒ WASHING ⇒ SORTING ⇒ CUTTING ⇒

BLANCHING ⇒ DRYING ⇒ PACKING

Our Services

Pre-Sales Support: At Shanghai Gofun Machinery Company, our team of

specialized engineers excels in creating customized equipment lists

tailored to the unique requirements, capacity needs, local voltage

specifications, and workshop conditions of our clients. When

designing the production process, we meticulously consider

essential elements such as water supply, power availability, steam

requirements, and other relevant factors to ensure seamless

integration with our customers' operations.

Quality Assurance: Upholding the highest standards, all materials

used in our equipment are meticulously crafted from premium SUS304

stainless steel.

On-Purchase Assistance: Each machine is carefully manufactured in

strict accordance with contractual agreements and approved

drawings. Upon receiving full payment, we optimize the shipping

process to ensure prompt delivery. For international shipments, our

machines are securely packaged in sturdy wooden crates, accompanied

by detailed installation instructions.

Post-Purchase Support: Upon arrival at the buyer's facility, our

team promptly coordinates the installation of the machines. We

offer a one-year quality guarantee and are dedicated to providing

ongoing support and service throughout the entire lifespan of the

equipment.